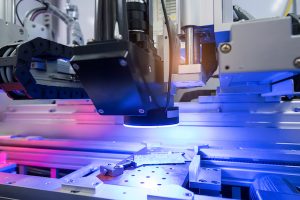

Machine Vision is the technology and methods used to provide imaging-based automatic inspection and analysis for many different applications. It is found in automatic inspection, process control, and robot guidance. It’s a term that encompasses a large number of technologies, software and hardware products, integrated systems, actions, methods and expertise. As a discipline within systems engineering, it can be considered distinct from computer vision, which is a form of computer science. It works to integrate existing technologies in new ways and apply those solutions to real world problems. The term is the prevalent one for these functions in industrial automation environments but is also used for these functions in other avenues such as security and vehicle guidance.

When compared to computer vision, industrial machine vision systems demand greater robustness, reliability, and stability compared with an educational/academic computer vision system and is typically less expensive than those used with government/military applications. Therefore, industrial machine vision is more cost effective, offers acceptable accuracy, high reliability, along with high mechanical and temperature stability.

Machine vision systems rely on digital sensors protected inside industrial cameras with specialized optics to acquire images, so that computer hardware and software can process, analyze, and measure various characteristics for decision making.

To that end, we offer a wide variety of precision lenses that are available to use in machine vision technologies.

By employing one or more video cameras – analog to digital conversion (ADC) and digital signal processing (DSP) – machine vision gives a computer the ability to see. The resulting data goes to a computer or robot controller. It’s fair to say that machine vision is similar in complexity to voice recognition.

Two important specifications in any machine vision system are the sensitivity and the resolution. Sensitivity is the ability of a machine to see in dim light, or to detect a weak impulse at invisible wavelengths. Resolution is the extent to which a machine can differentiate between objects. In general, the better the resolution, the more confined the field of vision. Though sensitivity and resolution are interdependent, all other factors held constant, increasing the sensitivity reduces resolution, and improving resolution reduces the sensitivity.

Machine vision is used in various industrial and medical applications. Examples include:

- Electronic component analysis

- Signature identification

- Optical character recognition

- Handwriting recognition

- Object recognition

- Pattern recognition

- Materials inspection

- Currency inspection

- Medical image analysis

No matter what type of application you require machine vision technology, we either have the correct lens for you, or our team of designers along with our manufacturing department will craft one that meets your unique specifications.