Most municipalities across the United States are drowning under the growing mounds of trash and recyclable materials. The situation is reaching epic proportions, as the refuse companies simply cannot keep up. Sorting trash with AI-assisted robots is one way they are working to stay on top of the problem.

Historically, China has recycled the bulk of U.S. waste. However, in 2018 China, the world’s largest recyclable processor, stopped accepting most of the U.S.’s scrap plastic and cardboard because of contamination problems.

While many people are beginning to work towards sustainability, the job of sorting and picking what is recyclable is most often left up to the individual companies that pick up the trash. Coupled with the rising cost of recycling, many municipalities are scrapping their programs all together, thereby increasing the amount of garbage in landfills and incinerators.

The AI-assisted robots – many of which have come online within the past year – are assisting human workers, and can work twice as fast. With continued improvements in their ability to spot and extract specific objects, they could become a formidable force in helping to streamline the $6.6 billion U.S. industry.

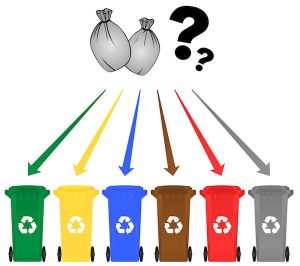

While containers are labeled as to how to sort for recycling, most people are still confused. At Simon Fraser Universities’ Surrey Campus, an AI-assisted robot named Oscar helps steer faculty and students in the right direction.

Oscar, developed and invented by an SFU student and an SFU alumnus, uses an AI-powered display and vision system to distinguish recycling from trash, offering visual cues to help users sort their waste items. The SFU Sustainability Office expects the robot to reduce the Surrey campus’s waste contamination rate from 70% to 20%, and play an important role in SFU’s award-winning Zero-Waste initiative.

The vision systems employed in these robots must be designed to ‘see’ items properly. At Universe Optics, we pride ourselves on ensuring that all of our precision lenses meet or beat your specifications. We offer a wide variety of lenses that are ready for purchase, or we will craft one designed especially for your robot.

Researchers like Lily Chin, a PhD. student at the Distributed Robotics Lab at MIT, are working to develop sensors for these robots that can improve their tactile capabilities and improve their sense of touch so they can determine plastic, paper and metal through their fingers. “Right now, robots are mostly reliant on computer vision, but they can get confused and make mistakes,” says Chin. “So now we want to integrate these new tactile capabilities.”

A Denver-based company, AMP Robotics is one of the companies on the cutting edge of innovation in the field. It’s software – an AMP Neuron platform uses computer vision coupled with machine learning – allows robots to differentiate between colors, textures, shapes, sizes and patterns to more clearly identify material characteristics so they can sort the waste. “Using this technology, you can increase the quality of the material and in some cases double or triple its resale value,” says AMP Robotics CEO Mantaya Horowitz. “Quality standards are getting stricter that’s why companies and researchers are working on high tech solutions.” According to Brent Bell, vice president of recycling at Waste Management. “Companies and municipalities have to invest in new technology to compete.” What robotics gives you with AI-assisted robots is a new way to boost efficiency and improve safety in facilities around the country. The hope is that many companies will begin to employ the new technology, and municipalities will get a handle on the trash and recyclable crisis.